Product Description

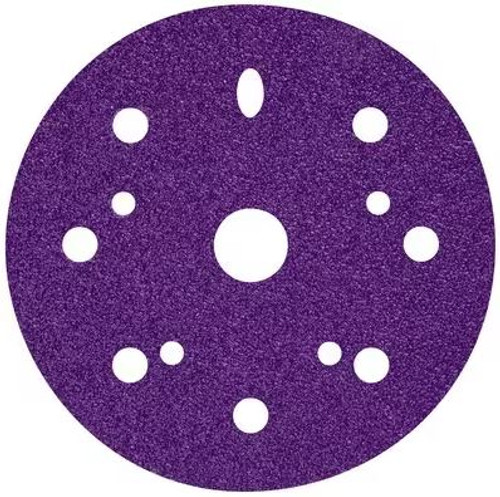

- Multi-hole discs evacuate dust to dramatically increase disc life

- Ceramic/aluminum oxide blend offers excellent cut rate and life for increased performance on composites and metal

- Open coat construction helps keep dust and debris from degrading performance

- Engineered specifically to resist edge shelling in heavy stock removal

- Hook-and-loop attachment makes swapping discs swift, simple and secure

3M™ Hookit™ Clean Sanding Disc 752I is one of 3M's best discs for heavy-duty sanding on composites and metal. An open coat ceramic and aluminum oxide blend is engineered to resist edge shelling during rugged use. The multi-hole disc design improves dust extraction when used with 3M™ Clean Sanding System tools. It is constructed on an E-weight paper backing with an anti-loading stearate coating.

Sharp-Cutting, Shelling-Resistant Abrasive Grain

Used with a vacuum system, our 3M™Hookit™ Clean Sanding Disc 752I features our 3M™ Clean Sanding technology to evacuate dust, increase cutting performance and dramatically increase disc life.

For dry-sanding stock removal on composites and blending metal, this disc is designed with a blend of 3M™ Ceramic Grain and aluminum oxide mineral. Its unique "stay sharp" crystalline structure continually reveals fresh cutting edges during use for an exceptionally fast and sustained cut. Engineered to increase the surface area of the grain and increase the surface bond, it resists shelling even during heavy stock removal.

Our Hookit Attachment System

Our 3M™ Hookit™ abrasive discs run cooler than pressure sensitive discs and conveniently attach to a hook-and-loop backup disc pad (sold separately). They can be removed cleanly and easily and re-used for the extent of the abrasive life. 3M™ Hookit™ discs work well in work spaces where adhesive-backed discs may become contaminated by dust or dirt.

Cut Dust

Discs cut and last longer when dust isn’t loading the cutting surface of the abrasives. 3M™ Clean Sanding technology reduces dust, keeping it away from the work surface, the abrasive and the air.

Optimized with a self-generated vacuum sanding tool fitted with a Clean Sanding filter bag (sold separately), Clean Sanding products allow the vacuum to suction dust from the air and off of the workpiece. This reduces loading of the disc and adds life to the abrasive. Additionally, reducing dust in the air improves working conditions. You can also pair Clean Sanding abrasives with Clean Sanding disc pads for use on a central-vacuum-ready sander.

Our multi-hole disc design allows a vacuum accessory to suck dust away from the work surface and reduce air-borne dust. This design doesn’t require alignment of holes with the disc pad so switching the discs is fast, easy and convenient.

3M Delivers

The broad footprint of 3M technologies shows in the many systems designed to work in concert to deliver superior performance, more cost-effective solutions and a process optimized to make work safer and simpler for operators who use our tools.